Resources

Explore our posters, videos, and other resources.

Additive Makerspace Tools

AMPLE's additive manufacturing capabilities go far beyond desktop 3D printing. Across the consortium, we use a diverse range of printers capable of working with concrete, wood-based materials, functional electronics, metals, and custom filaments - including advanced robot-assisted systems. From micro-droplet deposition and screen printing for printed electronics to large-format printing in the living environment, these technologies unlock new possibilities for functional prototyping.

Check out our posters below to learn moreSubtractive Makerspace Tools

Subtractive manufacturing tools shape materials by removing layers or sections to achieve the desired form. Across the AMPLE consortium, a variety of systems allow us to machine metals, composites, wood, fabrics, and more. These tools range from high-precision laser cutters capable of micrometre-scale detail to 5-axis CNC mills working in the centimetre range. These tools are essential for producing fine details, smooth finishes, and structural accuracy, supporting both prototype development and advanced fabrication across disciplines.

Check out our posters bellow to learn more

Supportive Makerspace Tools

Supportive tools play a crucial role in enhancing and streamlining the fabrication process across the AMPLE consortium. These include robotic arms, scanning systems, surface preparation systems, and characterisation and metrology equipment. These technologies ensure that complex processes run smoothly and consistently and bring greater understanding, quality, and control to every stage of production, supporting innovation across the consortium.

Check out our posters below to learn moreAdditive Makerspace Tools

Additive manufacturing tools create objects and patterns by building them up layer by layer from a variety of materials. These technologies enable efficient, precise, and highly customisable fabrication. Here are the additive manufacturing tools available across the consortium.

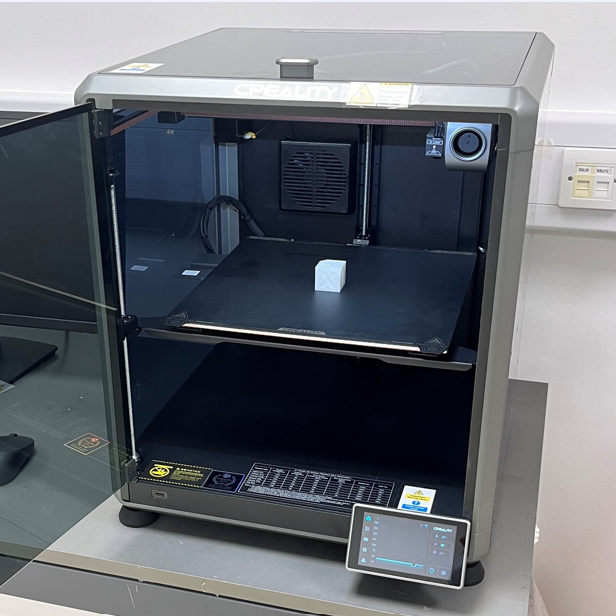

3D FDM Polymer Printer

This system is ideal for small scale production of parts and components at a rapid rate, making it ideal for prototyping. It is capable of printing in a variety of materials, each with different properties.

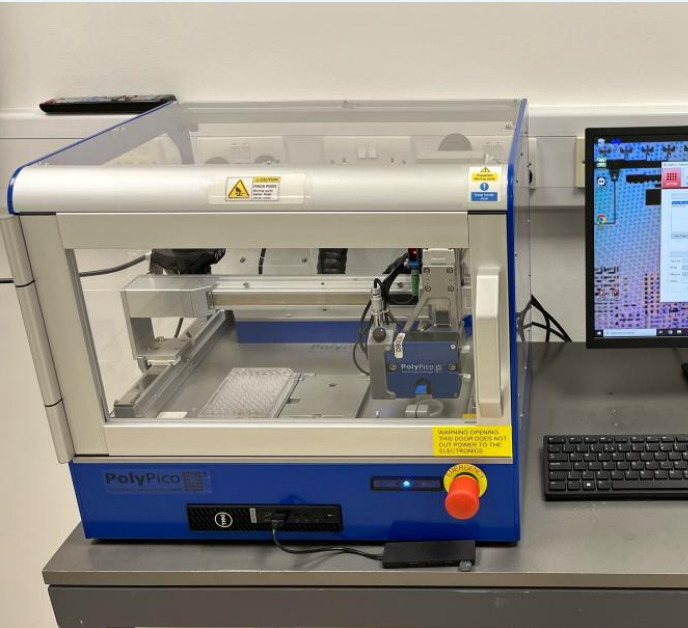

Microdroplet Dispenser

Piezoelectric micro-dispensing technology is used in precise fluid handling, giving high levels of control over the deposition of picolitre volumes of liquid. It's applications range from printing microcircuits and flexible circuits to cell cultivation.

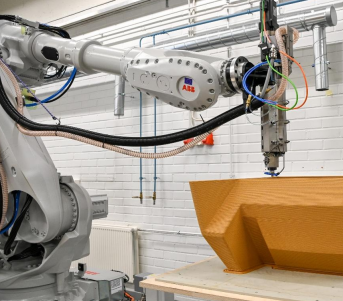

3D Printing Robot

Robot -assisted 3D printing using the fused deposition method (FDM) has emerged as a revolutionary technology for utilizing bio -based materials in special product design and fabrication of large -scale products.

Robot Assisted 3D Ceramic Printing

Robot -assisted 3D printing based on the extrusion deposition method represents a significant advancement in the use of ceramic and clay materials for the fabrication of large - scale design products.

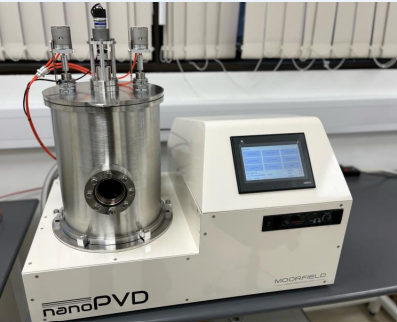

Thermal Evaporator

Evaporators are important tools for thin film deposition in research and industry. It allow us to create thin coatings for optical and electronic applications, to deposit metal layers for conductive and reflective purposes, and lots more applications.

Subtractive Makerspace Tools

Subtractive manufacturing tools shape materials by removing them from a larger block or sheet until the final form is achieved. These technologies offer precision, detail, and surface quality ideal for creating functional parts and prototypes. Here are the subtractive manufacturing tools available across the consortium.

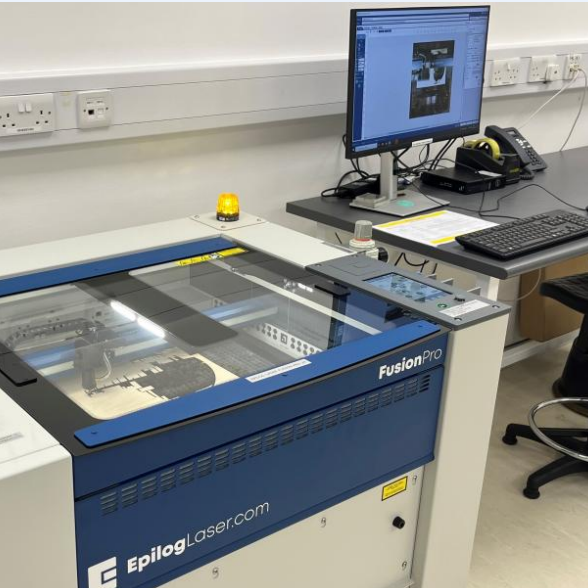

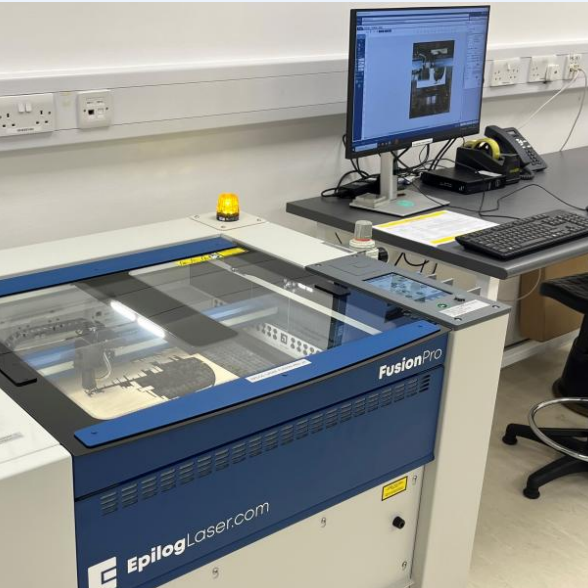

Epilog Laser Cutter

This system enables high-precision cutting of various materials, including card, wood, and acrylics. It is also capable of engraving intricte designs, toolpaths, and text onto materaials making it an ideal tool for making laser marked QR codes and ID tags. It is an ideal tool for rapid prototyping of parts and fixtures.

CO2 Laser Cutting And Engraver Machine

A CO₂ laser cutting system enables high -precision, contact -free processing of non -metallic materials such as wood, acrylic, leather, and textiles.

Supportive Makerspace Tools

Supportive tools assist and improve the design, fabrication, or testing process. They do not directly shape and create the part but provide essential functions like scanning, measuring, or robotic material handling.

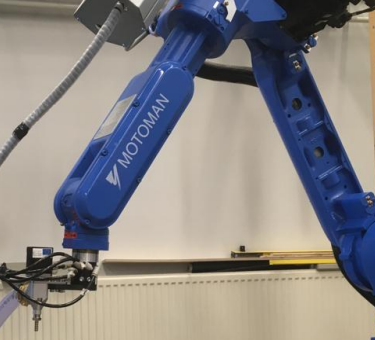

Robot Assisted Manufacturing

Robotic systems are beneficial in process automation, ensuring accuracy and repeatability, as well as optimizing production speed. In addition, they enable data collection and analytics, which can improve production line monitoring, predictive maintenance, and resource management

Digital Microscope

The keyence digital microscope allows us to examine objects from 20x up to 6000x magnification.

Surface Profilometry

This is a powerful non-contact surface metrology technique which allows us us to detect defects, evaluate thin films, study the surface of materials, and more.